Quantum Leap – April 2017

OTC 2017—COME SEE US IN ACTION

The Offshore Technology Conference (OTC) and exhibition will be held, as always in Houston Texas from May 1st to 4th this year.

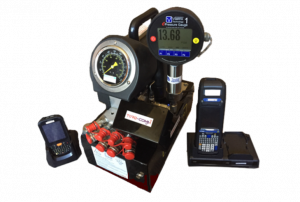

We will be attending the show with our recently signed OEM partners Torq/Lite and demonstrating just how user friendly our industrial bolting data collection and pump control systems are.

We’ll also have some clever little complimentary products to show you at the same time which all add to the ease of use, accuracy and failsafe features on offer.

So, if you are planning to attend the OTC, make sure you call by for a chat and a demonstration at booth 1301. We look forward to seeing you there!

A SOBERING LESSON IN VERIFYING BOLT LOAD

If anybody ever doubted that verifying the correct residual load in each and every bolt is key critical in indus- trial bolting applications, read on.

On December 24th 2015 a three-year-old wind turbine collapsed across a road at the Lemnhult wind farm in Sweden. The road was only for access and nobody was injured or killed but the image shows the devastation and provokes a sobering thought about what may have happened were the turbine in another location.

Swedish officials have pointed to incorrect bolt installation as the root cause of the collapse and Govern- ment accident investigation authority SHK said there were clear signs of fatigue and corrosion at the join between the bottom and second section of the tower.

“The bolts that had held together the joint had suffered from a fatigue process and the bolts could no longer withstand the loads of normal operation. The flange surfaces in the main wind direction showed signs of corrosion which most likely originated from the bolts.”

SHK said the cause of the fatigue was “the pre-tension force in the joint was too low”. It said the reason for not achieving the required standard “was due to the bolts, tower sections and tools not being protected from rain and snow during installation”. SHK added that the tools were not maintained properly and that the assembler who performed final torqueing of the bolts “had no previous experience” and “had not received the manufacturer’s internal training”.

Last year a turbine suffered a similar bolt failure at a wind farm in Hawaii, albeit at the top of the tower. Incorrect tensioning was again the main suspect.

So, be it torque or tension, verification that the bolts are tightened correctly is critical. Even with inexperienced operators, were the Torq-Comm Commander system in use in either of these cases, the bolt tight- ness would be guaranteed and the catastrophic failures completely avoided.

GLOBAL PARTNER SPOTLIGHT

In this regular feature, we will be introducing one member of our rapidly growing team of global partners. We work with a wide range of partners from OEM’s to exclusive distributors with one common denominator—we ensure all our partners are fully trained and supported before unleashing them on you. This ensures you will receive the same support from them as you would if you contacted our techies and boffins in our US head quarters.

Our first spotlight is on CK Energy Services, our exclusive distributor based in Perth Australia. Run by Keith Howlett, an ex-pat Englishman and Middlesbrough FC supporter (we won’t hold that against him ED). Keith cut his teeth in the UK Oil & Gas industry developing business in pipeline isolation tools from 1993 to 2005 before emigrating to Australia. He now runs his successful business, supplying pipeline isolation equipment to his clients and representing some select UK OEM’s.

Our first spotlight is on CK Energy Services, our exclusive distributor based in Perth Australia. Run by Keith Howlett, an ex-pat Englishman and Middlesbrough FC supporter (we won’t hold that against him ED). Keith cut his teeth in the UK Oil & Gas industry developing business in pipeline isolation tools from 1993 to 2005 before emigrating to Australia. He now runs his successful business, supplying pipeline isolation equipment to his clients and representing some select UK OEM’s.

Keith commented “what I like about Torq-Comm is the data is in your hands and the Cloud. It’s dials out human error—simple!”

We wish you and your team every success Keith!

A VERY HAPPY CUSTOMER WINS A CONTRACT THANKS TO THE COMMANDER XT1000

We can tell you all day, every day, how wonderful our products are but don’t take our word for it, listen to our happy customers:

Our customer, DARK Energy Solutions was given a challenge to secure a bolting contract from a major corporation. They were asked to quote for the provision of real time data acquisition during bolting operations. Despite being well established in the bolting industry, DARK Energy Solutions wasn’t aware of any technology that could meet this requirement. They had almost given up and missed out on the contract when a contact suggested they try Torq-Comm.

Our customer, DARK Energy Solutions was given a challenge to secure a bolting contract from a major corporation. They were asked to quote for the provision of real time data acquisition during bolting operations. Despite being well established in the bolting industry, DARK Energy Solutions wasn’t aware of any technology that could meet this requirement. They had almost given up and missed out on the contract when a contact suggested they try Torq-Comm.

Within seven days, DARK Energy had a Commander XT1000 unit in hand and were receiving user training over the phone due to time constraints. It is a testament to the user friendliness of the product as the trainees weren’t particularly computer literate.

In no time at all, DARK Energy personnel were on site, completing the bolting operations. The end user was delighted that they could watch the bolting operation, real time, per bolt and store the data for future reference. Date, time, GPS location, operator and tool identification and many other parameters were tagged with the data collect- ed.

DARK Energy Solutions contact Aaron V. commented “The system was so easy to set up and use and the technical support was phenomenal. Justification is a no brainer. I can’t say enough good about this system and I believe it will revolutionize the industrial bolting industry. Highly recommended!”

There really is no better advert for a company than a happy customer.