Exodys Software

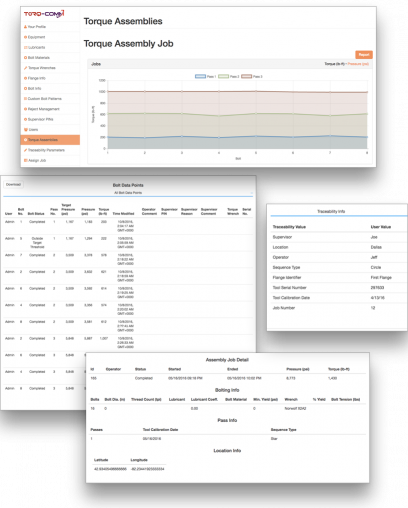

Administrative control center creation of assembly jobs, maintaining libraries of pertinent information, and the storage and reporting of all collected data.

Features:

- Global live viewing, analysis, and job creation for production control

- A library of bolting standards for Commander XT access

- Extensive reporting options include:

- Out of Spec issues

- Calibration, assembly data

- Flange Assemblies Detail

- Map Assembly Location & Drill Down

- Operator Performance

- Job Status

- Data export options include PDF and CSV

Exodys Cloud Storage

Automatic data transfer to the cloud makes this system as simple as it gets allowing a single person to control the wrench, the pump and the data. Flexible data collection options includes:

- Immediate transfer to our server for storage

- Storage on the Commander for later upload

Exodys Reports

The Torq-Comm system is a Process Control system that checks the Operator’s work in real time.

If the torquing for a specific bolt is not to specification, the Supervisor has the authority to accept or reject the torquing. If they reject the torquing, the Operator has to retighten. If they accept it, it is noted on the report and an email is automatically sent to management.

- Operational oversight

- Supervisory approvals

- Highly visible, highly specific